Technology isn’t limited to electronic devices anymore. Gone are the times when any advancements in technology were directly correlated to mobile devices, computers and televisions. Since the first 3D printer was developed in the mid 1980s, implications of the same have seen no limit. Recently, a fully-functioning heart was produced with the help of a 3D printer, which opened the path to many more organs that can be replicated with the help of the same. As per recent reports, a professor at the University of Southern California’s Viterbi School of Engineering formulated 3D printable rubber, that can “fix” itself.

Qiming Wang, three of his students and a professor from the University of Connecticut were able to achieve the aforementioned feat via a kind of rubber developed from silicone. As per their statement, a self-healing rubber sole for a sneaker may soon be a reality. Not only sneakers, in fact, the material can be used to 3D print objects like toys and tires. What’s more, even parts of satellites can be developed from the same material for improved resilience.

Healing Mechanism

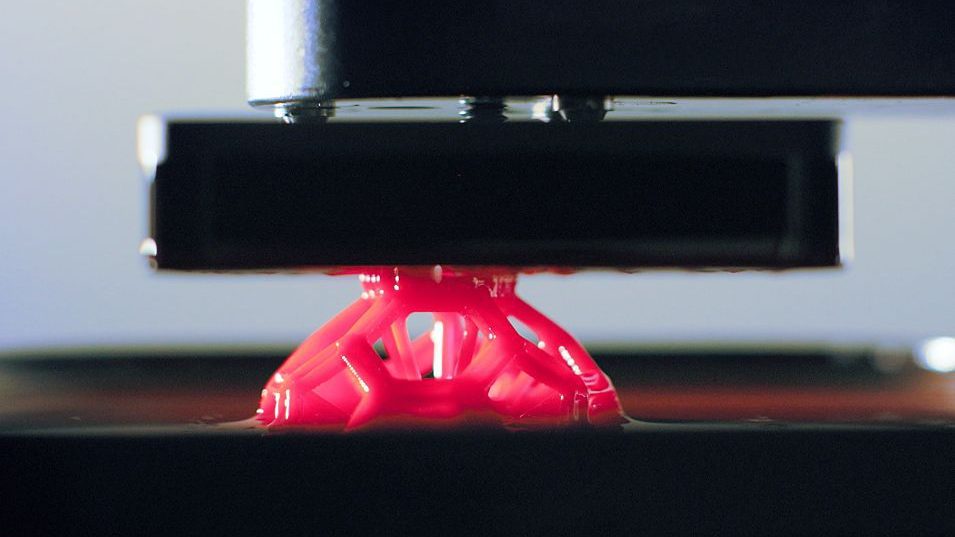

When the rubber material is exposed to a source of heat, a chemical reaction occurs that enables the atoms of the material to fuse back together. The healing speed is directly proportional to the amount of heat provided to the material, the report states. However, the healing process can occur at room temperature too. It will just take more time.

When the rubber material is exposed to a source of heat, a chemical reaction occurs that enables the atoms of the material to fuse back together. The healing speed is directly proportional to the amount of heat provided to the material, the report states. However, the healing process can occur at room temperature too. It will just take more time.

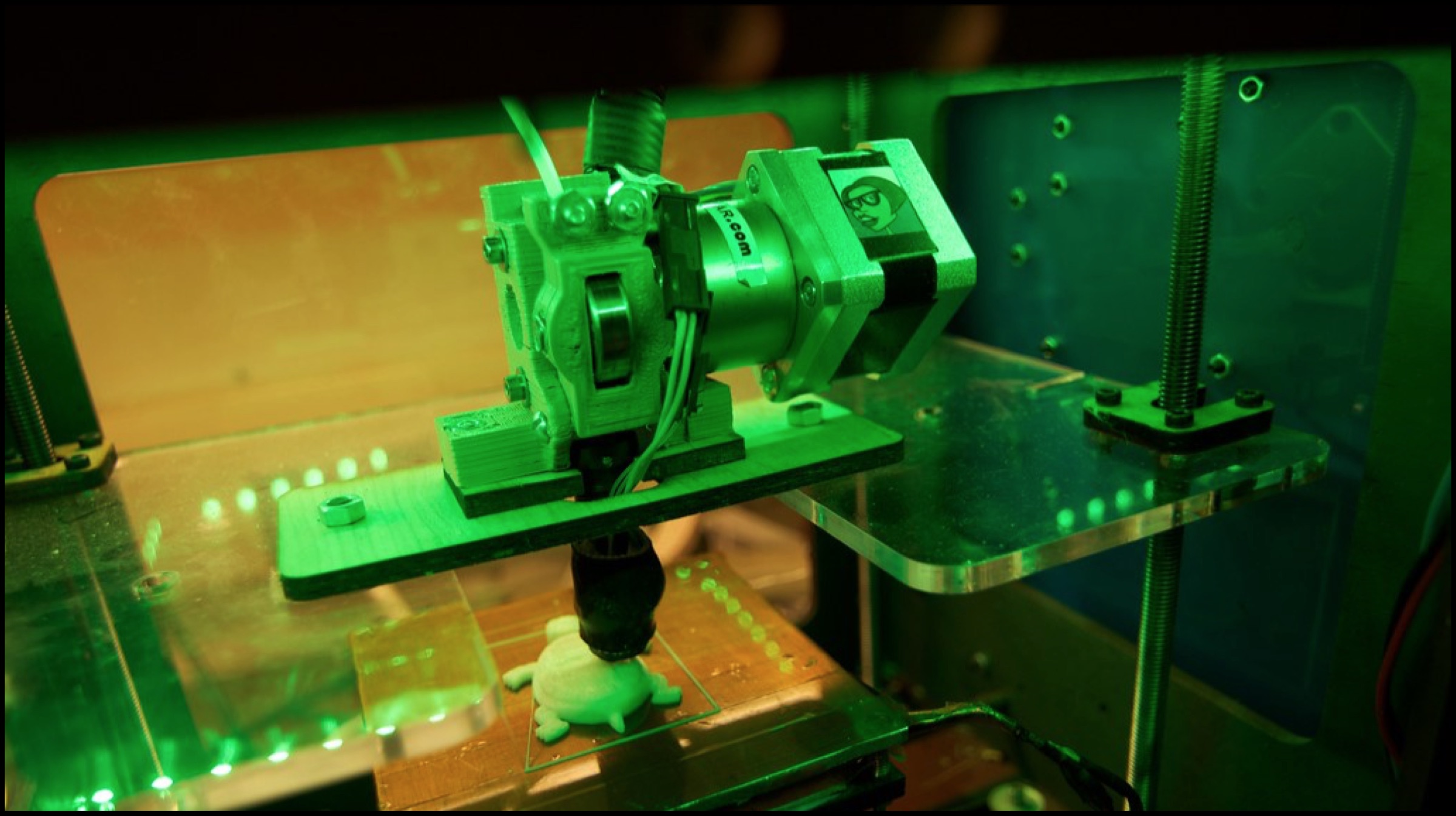

The report further states that the first step towards developing a self-healing object is to structure a model of the same in the computer. The software “slices” the 3D model into 100 smaller images, which are then projected onto a thin rubber layer (in liquid form). The rubber morphs into the shape of the original image, which is then converted to solid form using the projected light. Following a similar method, the complete shape is built up layer by layer, until the object is developed.

Concerns And Future Implications

Also Read: Scientists Replicate Highly Effective Anti Tumour Antibiotic To Fight Cancer

Also Read: Scientists Replicate Highly Effective Anti Tumour Antibiotic To Fight Cancer

Because of the concern that some structural issues may arise during the testing and development of such objects, Qiming Wang states that his team will experiment with multiple hardness levels in order to make the rubber sole wearable in all conditions. Furthermore, they will also experiment with ragged edges and their healing process, so that the material may regain its original shape and not be affected by any wounds and punctures. Already, Wang and his team have been contacted by multiple footwear companies to use the material for their upcoming shoes. Wang believes that self-healing sneakers will make their way into stores in 2-3 years, and the same material will someday be used for creating Airplane wings as well.